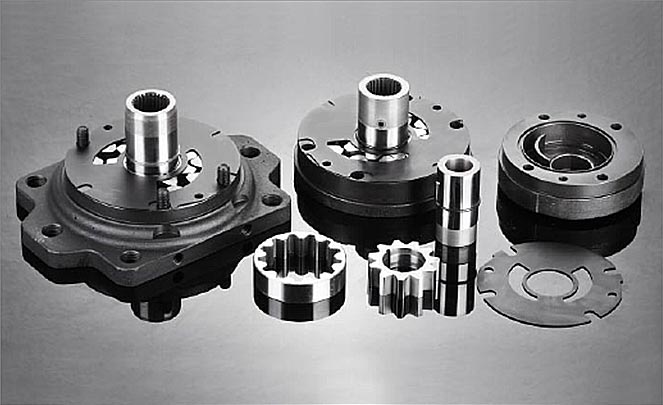

Rexroth A4VG Series Charge Pump Hydraulic Spare Parts

Our factory has multiple brands REXROTH,HITACHI,SAUER DANFOSS etc.. hydraulic pump parts, pump, motor of good quality and reasonable price in stock, which can be delivered to customers in the first time .contact us to confirm more details !

We provide our features product Rexroth A4VG Charge Pump with displacement A4VG 28,A4VG40,A4VG56 etc...Hydraulic Parts For above all we can guarantee 100% interchangeable and tested. Besides we also can offer A4VG Charge Pump Assembly and A4VG Piston Pump Assembly. Welcome send enquiry to us.

If you need A4VG charge pump,come to find us is your best choice, we can offer full series displacement product include A4VG 28~250 etc..A4VG charge pump provide cooling oil to the system and reduce the temperature of the system.By the way maintain the pressure of the main system circuit.If you are looking for more hydraulic pump parts then click here

We also provide A4VG pdf download support. Please contact us

Introduction

1. Provide cooling oil to the system and reduce the temperature of the system.

2. Maintain the pressure of the main system circuit.

3. And provide control pressure to the control loop, the control pressure of the system is generally designed to be the same as the charge pressure.

4. Replenish the loss of internal fluid. In order to avoid damage to the transmission under any driving and braking conditions, the charge pressure must be set at the specified pressure.

5. The charge pump is generally a gear pump, or an external gear pump or a cycloid gear quantitative pump, installed on the main pump and driven by the main shaft of the main pump. The charge pump pressure is limited by the charge relief valve.

6. The standard charge pump is suitable for most pumps. If the displacement of the charge pump is insufficient, you need to increase the displacement of the charge pump or install a gear pump on the auxiliary spline of the main pump to provide the necessary Extra oil.

Model Display

|

Item |

Description |

Model |

Number of Tooth |

Number of Tooth |

|

1 |

A4VG28 |

16 |

|

|

|

2 |

A4VG28 |

16 |

|

|

|

3

|

A4VG40 |

15 |

9 |

|

|

13 |

||||

|

15 |

||||

|

4 |

A4VG40 |

15 |

9 |

|

|

13 |

||||

|

15 |

||||

|

5 |

A4VG40 |

15 |

|

|

|

6 |

A4VG56 |

21 |

9 |

|

|

13 |

||||

|

7 |

A4VG56 |

21 |

|

|

|

8 |

A4VG71 |

22 |

14 |

|

|

13 |

||||

|

9 |

||||

|

9 |

A4VG71 |

22 |

14 |

|

|

13 |

||||

|

9 |

||||

|

10 |

A4VTG71 |

22 |

|

|

|

11 |

A4VTG90 |

24 |

|

|

Item |

Description |

Model |

Number of Tooth Front |

Number of Tooth Rear |

|

12 |

A4VG90 |

24 |

13 |

|

|

13 |

A4VG90 |

24 |

14 |

|

|

14 |

A4VG125 |

26 |

13 |

|

|

15 |

A4VG125 |

26 |

13 |

|

|

16 |

A4VG125 |

26 |

14 |

|

|

17 |

A4VG180 |

30 |

13 |

|

|

18 |

A4VG250 |

27 |

|

|

|

19 |

A4VG250 |

27 |

13 |

|

|

20 |

A10VG28 |

16 |

9 |

|

|

21 |

A10VG45 |

15 |

15 |

|

|

22 |

A10VG63 |

22 |

9 |

About Tansportation

Cooperation Partners

Contact us

Visen

Sales Manager

Company Introduction

Qingdao Runfeng Hydraulic Co., Ltd. has more than ten years of experience in hydraulic parts production and international trade. We use the highest quality raw materials for production and provide the highest quality accessories available worldwide. We are your trusted supplier of hydraulic components in China.

Here, you can not only get the best quality accessories, but also get the best service and long warranty period.

Exquisite transportation packaging, fast shipping service, and high-quality accessories make us the best choice for you.

Product Application

Engineering Plant

Hydraulic pumps and motors on equipment such as excavators, pavers, rollers, drills, bulldozers, heavy excavators, road mixers, etc.

Construction Machine

Hydraulic pumps, motors, etc. on concrete pump trucks, concrete pump truck transporters, concrete mixer trucks, pile drivers and other equipment.

Industrial Equipment

Hydraulic pumps and motors on polyurethane foam machines, ceramic presses, plastic machinery, chemical equipment, metallurgical equipment, etc.

Ship Aviation

Towing ship machine. Anchor cranes, cranes, dredgers, dredging vessels, etc. are used in ship control systems and hydraulic pumps and motors in operating systems.

Details Introduction of Charge Pump

First look at the function of the charge pump in the closed system:

We must first know the role of the charge pump, what are its role and auxiliary role.

1: Provide cooling oil to the system to reduce the temperature of the hydraulic system.

2: Maintain the pressure of the main system loop.

3: Provide controllable pressure to the control loop. The control pressure of the system is generally designed to be the same as or lower than the pressure of the charge pump.

4: To supplement the oil loss of internal leakage, in order to avoid damage to the transmission under any driving and braking conditions, the pressure of the charge pump must be set at the specified pressure.

The structure principle of the charge pump

The charge pump is generally a gear pump, or an external gear pump or a cycloid gear pump. It is installed on the main oil pump and driven by the main shaft of the main oil pump. The charge pump is generally limited by a separate charge relief valve.

First of all, you need to know the charge pressure detection. The charge pressure detection port is different according to the different detection positions of the oil pump model and manufacturer. The detection port of the Rexroth series is marked; PS.., this port is the location for detecting the charge pressure.

Analysis of the reason why the normal pressure of the charge pump is between 2.8 and 3.4Mpa that affects the abnormal pressure of the charge pump:

1: The charge pump is severely worn or damaged. Solution: Replace

2: The charge relief valve is stuck or adjusted incorrectly. Solution: clean or adjust

3: The oil inlet filter element of the charge pump is blocked or the oil inlet is not smooth. Solution: Check the filter element, clean or replace.

4: Wrong flushing pressure, solution: adjust or replace flushing valve

5: The damping of the parallel G port oil outlet is too large or fails. Solution: Check or replace the orifice connector.

Then take a look at the installation points:

We often see several problems in the closed system on pump trucks: the pressure of the charge pump is unstable, the control pressure is low, the number of reversing is not enough, etc. Most of the problems are caused by the charge pump itself. Today we will fix it. Several precautions for the installation of the oil pump are explained.

Points to note:

1: Pay attention to the chamfering direction of the large and small gear rotors and avoid installing them backwards.

2: Do not install the wrong direction of the side plate of the charge pump. The correct direction can cover the crescent position and install the screw normally.

3: The contact surface of the charge pump and the main pump where the charge pump is installed must be flat and free of impurities.

4: The fixed screw of the charge pump must be tightened with a torque wrench, not just by feeling.

5: The seal ring on the mounting surface of the charge pump must be of appropriate size, too thick or too small.

6: Before installing the main pump on the charge pump, determine the direction of rotation of the main pump. Do not install the wrong direction of the main pump.

7: After the charge pump is installed, fill in clean hydraulic oil and rotate the main shaft to see if the self-suction condition of the charge pump is reasonable.

8: If the main pump was broken and damaged before, the main pump must be thoroughly cleaned and repaired.

9: Check whether the guide copper sleeves before and after the charge pump are severely worn, replace them if necessary.

10: After the charge pump is installed with the main pump, check whether the drive shaft of the charge pump can move back and forth with normal clearance, and the fit cannot be too tight.

11: After the charge pump is installed with the main pump, check the concentricity of both sides.

12: Before loading, clean the entire hydraulic system, and change the hydraulic oil and filter element of the vehicle if necessary.

13: If the main pump is damaged, the main oil cylinder must be lifted and disassembled and cleaned. This must be implemented.

14: After the charge pump is installed with the main pump, the standard hydraulic test bench must be used to readjust the parameters.

15: The main pump flushing pressure will also affect the charge pump pressure and service life. The upper hydraulic test bench must be equipped with a flush valve for inspection and adjustment.

16: For specific parameters and torque data, please find a professional technician.

17: We provide you with a complete set of solutions, professional things are left to professional people to do